Natural smoke ventilation systems, often referred to as AOVs (Automatic Opening Vents) or NSHEVs (Natural Smoke and Heat Exhaust Ventilators), are common in many buildings. They typically include windows, skylights, or dedicated vents that automatically open during a fire to let smoke escape naturally.

These systems are valued for being cost-effective and relatively simple, with no large mechanical fans. However, “low maintenance” doesn’t mean “no maintenance”! To keep your natural vents reliable in all seasons, year-round, you need to implement regular checks and care. This article covers why year-round reliability can be an issue for natural vents and provides practical tips to for AOV Maintenance.

The Importance of Year-Round Reliability

A natural smoke vent that fails to open in a fire emergency is a disaster waiting to happen. While these systems have fewer moving parts than mechanical fans, they are still prone to issues over time and through seasonal changes:

- Dust and debris accumulation: Leaves, dust, and grime can build up around roof vents or in hinge mechanisms, especially during autumn and spring. If not cleaned, this debris can cause the vent to jam or open only partially. A vent that’s even partly obstructed can dramatically reduce smoke clearance efficiency.

- Corrosion and weather effects: External vents are exposed to weather all year. Rain and moisture can cause metal parts (hinges, chains, actuators) to rust or seize if they aren’t weather-resistant or lubricated. In winter, snow or ice accumulation can physically block vents from opening. Freezing temperatures might stiffen seals or gaskets. In summer, high heat and UV exposure can degrade certain plastics or rubber components.

- Lack of use leading to seizure: Paradoxically, the better the fire safety record, the less often your AOVs trigger – meaning the mechanism might sit idle for long periods. Any mechanical device can stiffen or seize if it’s not operated periodically. Without regular testing, you might discover too late that a vent’s motor has failed or the vent is painted shut from building works long ago.

Given these factors, it’s clear that regular maintenance of naturla smoke ventilation systems throughout the year is essential. Indeed, guidance like BS 9999 and the Smoke Control Association’s recommendations advise periodic testing and servicing of natural vents to catch these issues early. For example, natural smoke vent systems generally should have professional inspection at least every 6 months, even though they’re simpler than mechanical ones. They also benefit from weekly and monthly in-house checks to keep them operational.

Regular Checks and AOV Maintenance Tasks

To keep your natural smoke ventilation system reliable all year, consider the following maintenance routine:

Weekly “actuation” tests

Assign a Nominated Person (someone on your staff or maintenance team) to perform a quick weekly test of the AOV system. This can often be done via the fire alarm panel or a manual test switch – trigger one zone or one vent at a time on a rotating basis. The goal is to exercise the vents regularly so that they open fully and close properly.

Listen for any unusual noises from the actuator and ensure the vent actually opens to the correct angle. By testing one zone per week (or as per manufacturer guidance), you ensure each vent gets activated at least once every few weeks. Always log these tests in the system logbook.

Monthly visual inspection

Have a competent person do a more thorough check monthly. This should include: examining vent openings for debris or bird nests (clear any you find); inspecting hinges, pistons, or electric actuators for signs of corrosion, wear or damage; checking that manual release mechanisms (if any, like break-glass units) are intact; and verifying that control panels or indicator lights show normal status (no fault lights).

Also, simulate a power failure to ensure the backup batteries or failsafe open mechanism works – many AOVs have battery backups or spring-return actuators that open on loss of power. A monthly power-cut test ensures that, for example, if a fire knocks out the electrics, your vents will still open.

Seasonal cleanup and service

At least twice a year (e.g. spring and autumn), schedule a focused AOV maintenance service, ideally by a smoke vent specialist. In spring, you’ll clear any winter grit, check for rust from winter moisture, and ensure new plant growth (vines, etc.) isn’t encroaching on vents.

In autumn, clear fallen leaves and prep for winter: that might include applying a light lubricant to moving metal parts to prevent freeze-up, and checking any heating elements (some smoke vents have small heaters to prevent frost sticking) if applicable.

These biannual services align with industry guidance that natural systems should have competent maintenance roughly every 6 months. During these visits, the technician should also test smoke detectors or call points linked to the AOV, verify the control logic (often AOVs shut if wind or rain sensors are in use for dual-purpose vents), and replace any batteries that are nearing end-of-life.

Annual full service (and maybe weatherproofing)

At least once a year, get a certified smoke control engineer to do a comprehensive service. They will perform functional tests on every AOV, recalibrate sensors, test every interface (fire alarm signals, manual overrides, etc.), and provide a maintenance certificate.

According to the SCA’s maintenance guidance, an annual check by a certified engineer is essential for natural smoke vents. This yearly service is also a good time to consider weatherproofing upgrades: for instance, renewing worn-out rubber seals that keep rain out when vents close, or adding mesh guards if birds have been a problem.

The engineer should also confirm that the environmental features of the vent (if it doubles as a daily ventilation or rooflight) haven’t compromised its fire function – sometimes painting or retrofitting an AOV can inadvertently glue it shut.

An annual clean of the vent shafts or louvers might be needed to remove dust buildup (some guidance suggests smoke shafts be cleaned annually and certified).

Common AOV Maintenance Issues to Watch For

Through the year-round maintenance cycle, keep an eye out for common AOV problems that can develop:

- Vent failing to open fully: If a vent only cracks open or opens slowly, there could be a mechanical bind, a weak actuator, or obstruction. Dust and corrosion are often culprits. Address this immediately – partial opening drastically reduces smoke exhaust performance.

- False triggers or failure to trigger: Ensure your detection system (smoke sensors or manual call points) that triggers the AOV is working. Sometimes an AOV might not open when it should due to a sensor wiring issue or control panel fault. Regularly test the trigger devices. Also verify that fireman’s override switches (if installed) properly open the vents – a firefighter should be able to manually activate ventilation.

- Water ingress or drafts: After heavy rain, check if any water leaked through a closed vent; this could indicate seal problems. Similarly, in winter, a drafty vent might need seal replacement. While not directly a fire safety issue, poor seals can cause other building issues and hint at degraded components.

- Power supply/battery issues: Natural vents often rely on the building’s power (with battery backup). If the backup battery is low, the system might show a fault on the panel. Don’t ignore those signs – replace batteries as recommended (usually every 3-5 years, or as flagged by maintenance). A vent that fails to open due to a dead backup battery during a power-cut scenario defeats its purpose.

- External interference: Occasionally, external factors like painting, roofing works, or retrofit installations can interfere with vents. There have been cases where contractors inadvertently painted over vent hinges or sealed a vent shut during facade works. After any building work near your AOVs, double-check the vents’ freedom of movement.

Staying ahead of these issues with proactive Natural Smoke Vent maintenance is far easier and cheaper than dealing with a failed vent in an emergency (or a major repair later). It also ensures your system remains compliant with fire safety regulations year-round, not just at inspection time.

The Payoff: Confidence in an Emergency

A properly maintained natural smoke ventilation system offers peace of mind in every season. If a fire breaks out on a freezing January night, you can be confident that the stair vents will pop open despite the cold, keeping escape routes clear of smoke. If a blaze occurs on a sweltering July afternoon, you know the vents will already have been tested and free of any dirt that could impede them. Essentially, you’re ensuring the system’s performance reliability 24/7, 365 days.

Natural vents are an elegant fire safety solution when they work as intended. By investing a bit of time in year-round upkeep, you preserve that life-saving simplicity. As one maintenance guide succinctly puts it: even simple AOV systems “still need actuator, hinge, and sensor testing” on a routine basis. Do that, and your vents will reward you with dependable operation for years to come.

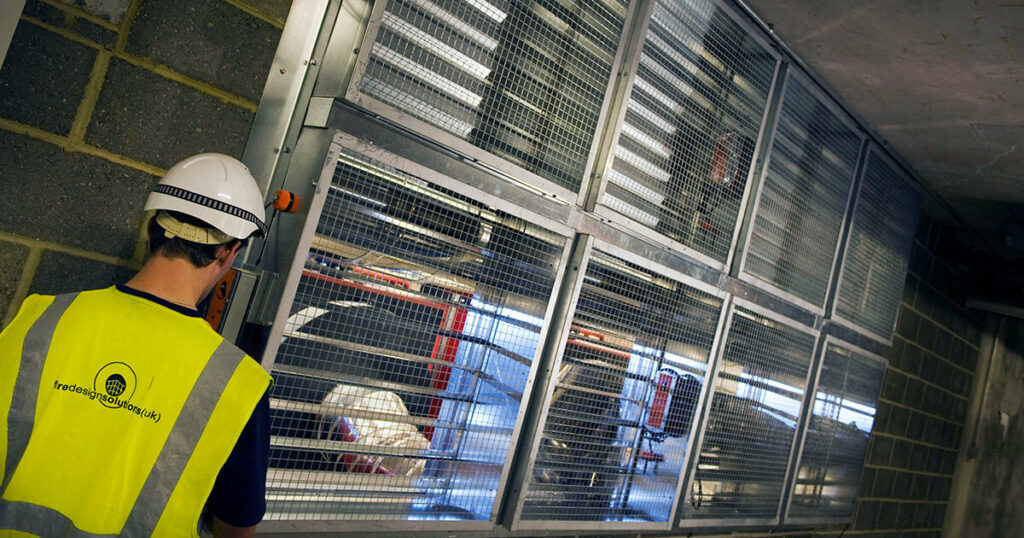

Want to ensure your smoke vents operate flawlessly in every season? FDS Maintenance specializes in natural smoke ventilation upkeep, from spring cleaning of vents to winterproofing and regular testing. Our expert team will keep your AOVs and NSHEVs in peak condition year-round, so you never have to worry about a vent sticking when it matters most.

Contact FDS Maintenance today for a AOV maintenance plan that keeps your natural smoke vents reliable, come rain or shine.